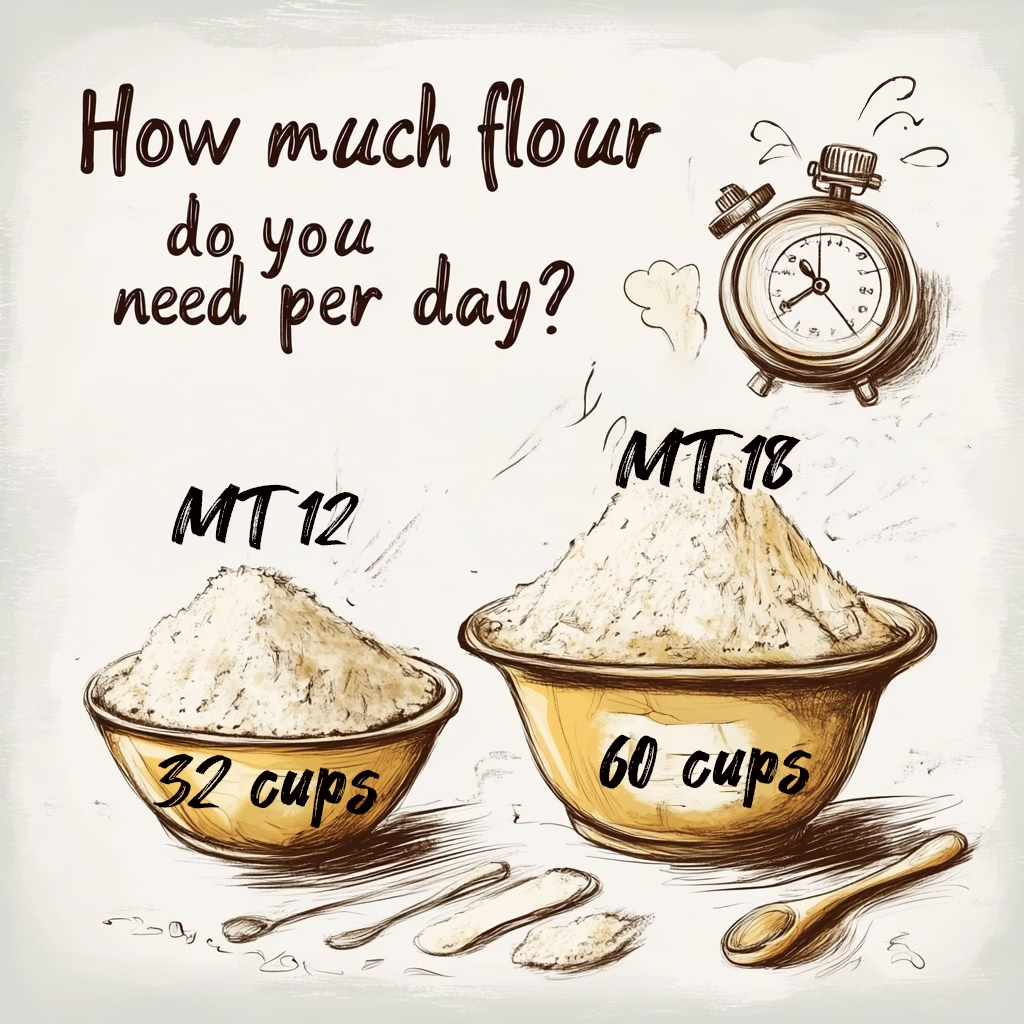

What is your daily flour requirement? Choosing the right flour mill is crucial to efficiently meeting your flour needs at home. This guide contains important information to help you find the perfect grinder for your daily flour needs.

Choose a grinder that can grind your daily flour requirements in a single pass.

Professional tip: If you need significantly more flour on certain baking days, you should grind half of the required amount the day before to keep the amount within the mill’s operating limits.

By considering these capacities in relation to your daily flour requirements and the types of grain you want to grind, you can make an informed decision and choose the grain mill that best suits your household.

Place the grain in an open container (not in freezer bags or plastic containers) so that no ice film forms on the grain.

Place the grain in an open container (not in freezer bags or plastic containers) so that no ice film forms on the grain.

Please differentiate between grain storage and cooling:

It is sufficient to put the grain in the freezer MAXIMUM one day before use.

The exact amount of flour that a mill can produce in one cycle depends on several factors:

Note: If grinding hard grains frequently is important for you, pay close attention to the specific model capacities below, as these grains are more challenging for domestic mills.

The finer you grind and the harder the grains are, the more heat is generated in the grinding chamber.

The rising heat causes the moisture content of the grain to evaporate. The resulting moisture is absorbed by the wooden grinding chamber. This positive effect regulates the humidity in the grinding chamber in a natural way. This positive effect cannot be observed with grinding chambers made of plastic or metal, where condensation can lead to clumping of the flour residues.

Wood is a biomaterial that swells and shrinks with changing water content in the wood structure, which goes hand in hand with natural climate regulation.

Whenever our wooden grinding chamber has absorbed large amounts of moisture during prolonged grinding, it is advisable to facilitate and accelerate the escape of moisture by opening the grinding chamber for ventilation.

After an appropriate drying phase, which depends on the relative humidity and temperature of the place, the hopper can be reassembled to be ready for another healthy and happy use of your Salzburg grain mill.

There are 2 reasons for this: We avoid the abrasion of plastics and prevent the formation of mold.

Wood is a natural material. In our grinding chamber made of natural and untreated wood, the grain can cause only minimal abrasion over many years, so you are guaranteed not to find any microplastics in your food.

Wood is a natural material. In our grinding chamber made of natural and untreated wood, the grain can cause only minimal abrasion over many years, so you are guaranteed not to find any microplastics in your food.Plastic cannot absorb moisture.

Try it out for yourself and store moist food in plastic. Observe the change in consistency and taste. You will also notice mold growth within a very short time.

It is therefore understandable why bread is always stored in wooden containers or breathable linen bags or paper and not in plastic bags or plastic containers!

Stored in a natural way, the bread stays tasty, fresh and mold-free for much longer! Further proof that our wooden grinding chambers are the better choice.

Address:

Gasteigweg 25,

5400 Hallein

Austria

Opening hours:

Monday to Thursday: 09 – 16:00

Friday: 09 – 12:00

Contact:

Phone: +43 6245 83282

E-mail: info@agrisan.at

Address:

Gasteigweg 25,

5400 Hallein

Austria

Opening hours:

Monday to Thursday: 09 – 16:00

Friday: 09 – 12:00

Contact:

Phone: +43 6245 83282

E-mail: info@agrisan.at